How to Choose the Right Wire Cable for Your Electrical Project

Choosing the right wire cable for your electrical project is a crucial step that can significantly impact the performance and safety of your installation. With the vast array of wire cables available on the market, it can often feel overwhelming to determine which type is best suited for your specific needs. Factors such as gauge, insulation type, and application purpose play vital roles in ensuring that your wiring will handle the electrical load and provide reliable service.

In this guide, we will explore the essential criteria to consider when selecting wire cable for various electrical applications. Understanding the characteristics of different wire types, including their capacity to handle current and resistance to environmental factors, will empower you to make informed decisions. Whether you are embarking on a small DIY project or a larger electrical installation, knowing how to navigate the selection process for wire cable is key to achieving both safety and efficiency in your electrical work.

Understanding Wire Gauge: The Importance of AWG in Cable Selection

When it comes to selecting the appropriate wire cable for your electrical project, understanding wire gauge, specifically the American Wire Gauge (AWG) system, is crucial. The AWG system defines the standard wire sizes in the United States, which helps determine the current-carrying capacity of the wire. Each gauge represents a specific diameter, with smaller gauges indicating thicker wires capable of handling more current. For example, a 12 AWG wire can handle up to 20 amps, making it suitable for many residential applications, while a 14 AWG wire is rated for 15 amps. According to the National Electrical Code (NEC), using the correct gauge is essential for safety, as using an undersized wire can lead to overheating and potential fires.

Moreover, the impact of wire gauge on voltage drop cannot be overlooked. A report by the U.S. Department of Energy highlights that inadequate wire sizing can create significant voltage drops, leading to inefficiencies in electrical systems. For instance, a 120-volt circuit with a 14 AWG wire over a distance of 100 feet can experience a voltage drop of approximately 3 volts at 15 amps – about 2.5% of the total voltage. This drop can diminish the performance of appliances and affect their lifespan. Understanding these critical factors allows project managers and homeowners alike to make informed decisions when selecting wire cables, ensuring both efficiency and safety in their electrical installations.

Evaluating Conductor Material: Copper vs. Aluminum for Electrical Efficiency

When it comes to choosing the right wire cable for your electrical project, understanding the conductor material is crucial. The two most commonly used materials are copper and aluminum, each with its unique benefits and drawbacks. Copper is renowned for its excellent electrical conductivity, which is significantly higher than that of aluminum. This attribute allows for increased efficiency in power transmission, as it minimizes resistance and energy loss. Additionally, copper's superior durability makes it a reliable choice for various applications, especially those that require consistent performance over time.

On the other hand, while aluminum has a lower conductivity than copper, it is much lighter and more cost-effective, making it an appealing option for projects where weight and budget are significant considerations. Aluminum wires are easier to handle and can be particularly advantageous for overhead power lines. However, they require larger diameters to match the conductive capacity of copper, potentially leading to increased space requirements. Moreover, aluminum is susceptible to corrosion, which may compromise its electrical performance over extended periods. Therefore, evaluating the specific needs of your project is essential when deciding between copper and aluminum conductors to achieve optimal electrical efficiency.

Determining Voltage and Current Ratings: Key Factors for Safe Wiring

When embarking on an electrical project, one of the most crucial aspects to consider is the voltage and current ratings of the wire cable. These ratings define the capacity of the wire to safely carry electrical current without overheating or succumbing to damage. According to the National Electrical Code (NEC), a common guideline is that wire should be rated for at least 125% of the expected continuous load. For example, if you anticipate a continuous load of 20 amperes, selecting a wire rated for at least 25 amperes is advisable. This buffer helps mitigate risks associated with unexpected surges, ensuring a safer installation.

In addition to voltage and current ratings, understanding the wire's ampacity—its ability to handle current flow—is essential. Ampacity can vary greatly depending on factors such as the wire's gauge, insulation type, and ambient temperature. The American Wire Gauge (AWG) standard provides a comprehensive framework for determining these properties. For instance, a 12 AWG copper wire can typically handle up to 20 amps when used in residential settings, while a 14 AWG wire is rated for only 15 amps. Depending on the specific requirements of your project, adhering to these guidelines ensures that your electrical system operates efficiently and safely, ultimately reducing the likelihood of fire hazards or component failure.

Assessing Environmental Conditions: Choosing Cables for Specific Applications

When selecting wire cables for specific electrical applications, assessing the environmental conditions is a crucial step that directly impacts safety and performance. Different environments present unique challenges, such as temperature extremes, moisture levels, and exposure to chemicals or UV radiation. For example, cables used in outdoor applications must be resistant to sunlight and weathering, while those in damp locations require waterproof insulation to prevent short circuits and maintain integrity over time. Therefore, understanding the specific environmental factors that the cable will encounter is essential for making the right choice.

Additionally, the mechanical stress and potential hazards associated with the installation location must be taken into account. In industrial settings, for example, cables may be subject to abrasion, vibration, or even impacts from equipment. Selecting cables with enhanced durability and flexibility can help mitigate these risks and prolong the lifespan of the installation. Furthermore, applications involving high safety standards, such as in hospitals or chemical plants, may require cables that comply with stringent regulations and meet specific fire resistance or low smoke emission criteria. By thoroughly evaluating the environment and application requirements, you can ensure that the selected wire cables will perform reliably and safely throughout their intended lifespan.

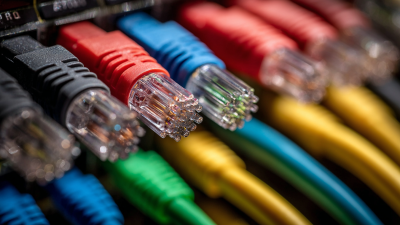

Identifying Cable Types: Insulation and Jacket Ratings in Electrical Projects

When selecting the right wire cable for your electrical project, understanding the various types of insulation and jacket ratings is crucial. Insulation materials, such as PVC, rubber, and XLPE, each have unique properties that determine temperature resistance, chemical stability, and overall durability in different environmental conditions. For example, according to the National Electrical Code (NEC), insulation ratings are often categorized by temperature, with common ratings including 60°C, 75°C, and 90°C. These ratings not only influence the performance of cables but also can impact safety and compliance with regulations.

In addition to insulation type, the jacket rating plays a vital role in protecting cables from external elements. The jacket is designed to resist abrasion, UV exposure, and moisture, making it essential for installations in harsh environments. Various jacket types are available, such as THHN (Thermoplastic High Heat Resistant Nylon-coated), which is often rated for wet and dry locations, and UF (Underground Feeder) cables designed specifically for direct burial applications. According to an industry report by the Insulated Cable Engineers Association (ICEA), selecting the correct jacket type can increase the longevity of the installation and prevent costly failures over time. As a project manager or electrician, understanding these specifications can ensure a successful and safe electrical installation.

Related Posts

-

2025 How to Choose the Right Wire Cable for Your Projects Effectively

-

Understanding Wire Cable Insulation: How It Impacts Safety and Performance in Electrical Systems

-

Why You Should Choose Fiber Optic Patch Cable for Reliable High Speed Internet Connection

-

Emerging Trends in HDMI Fiber Optic Cable Market at 2025 China Import and Export Fair

-

Harnessing Fiber Optic Adapter Innovations at China Import and Export Fair 2025

-

Unlocking High-Definition: The Essential Guide to Choosing the Right HDMI Adapters for Every Device